Basal Plate

| Type | Specialty | Application |

| Cold rolled steel | Its corrosion resistance is not good, low cost. | Metal furniture lining components, lamps, electrical boxes, etc |

| Galvanized steel | The zinc layer of hot galvanized sheet is thicker, suitable for preparing color coated sheet with higher anticorrosion and less decorative requirements. | Exterior wall board, roofing board, garage door, etc |

| Galvalumed steel | Production process and hot galvanized sheet basically the same, mainly regulate the composition of molten plating solution, according to the amount of aluminum content to classify. | Corrosive outdoor environment |

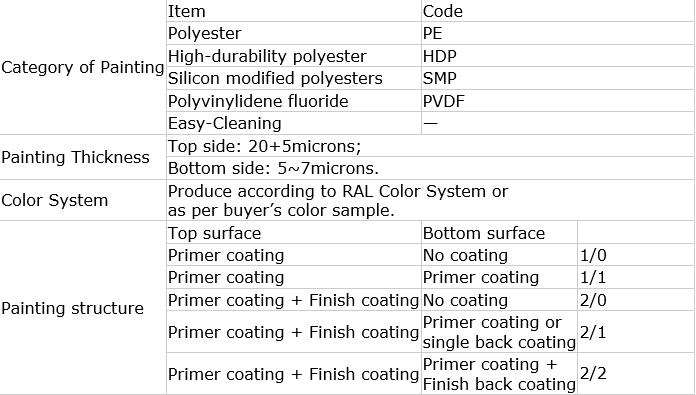

Painter

Ordinary polyester color coating products (PE) :

Features: the comprehensive performance is very good, its good weather resistance and mechanical processing performance, can fully meet the general requirements for building external use.

Epoxy primer: Epoxy system primer with excellent corrosion resistance and adhesion.PU primer: polyurethane primer with excellent machinability and corrosion resistance. Universal primer.

Scope of application: outdoor parts of industrial plant and commercial building, such as roof and outer wall.

Silicon modified polyester color coating products (SMP) :

Features: special silicone polyester resin and crosslinking agent to ensure adequate weather resistance;Use super weather resistant pigment to ensure the color of permanent bright;Special organosilicone structure, makes the coating harder, can increase wear resistance and metal scratch, can withstand the processing of stamping.

High durability polyester color coating products (HDP) :

Using high-performance polyester resin and inorganic ceramic pigments, you can do a lot of PVDF can not do color;Special polyester structure, good resistance to hydrolysis, the use of weather resistant pigments, and ordinary polyester coating has excellent chemical resistance and durability;Compared with ordinary silicon modified polyester, it has better processability and chemical resistance.

Polyvinylidene fluoride (fluorocarbon) color coating products (PVDF) :

More than 70% fluorocarbon resin content, so that the coating has a good weather resistance, acid and alkali resistance and environmental pollution performance;The coating all USES the advanced inorganic ceramic pigment, blocks the ultraviolet ray, causes the coating to have the luster to maintain and the color to maintain the ability;Also has excellent mechanical properties: such as t-bend up to 0-2t.