Application field of hot – dip aluminum – zinc products

1. Construction: wall panel, roof board, water pipe, fence, shutter, window frame

2. Automobile: muffler, door, oil filter,

3. Home appliances: explosion-proof belt, oven, vending machine, car stereo, refrigerator back plate, rice cooker, electrical components

4. Others: steel furniture, containers, mailboxes, sewing machines

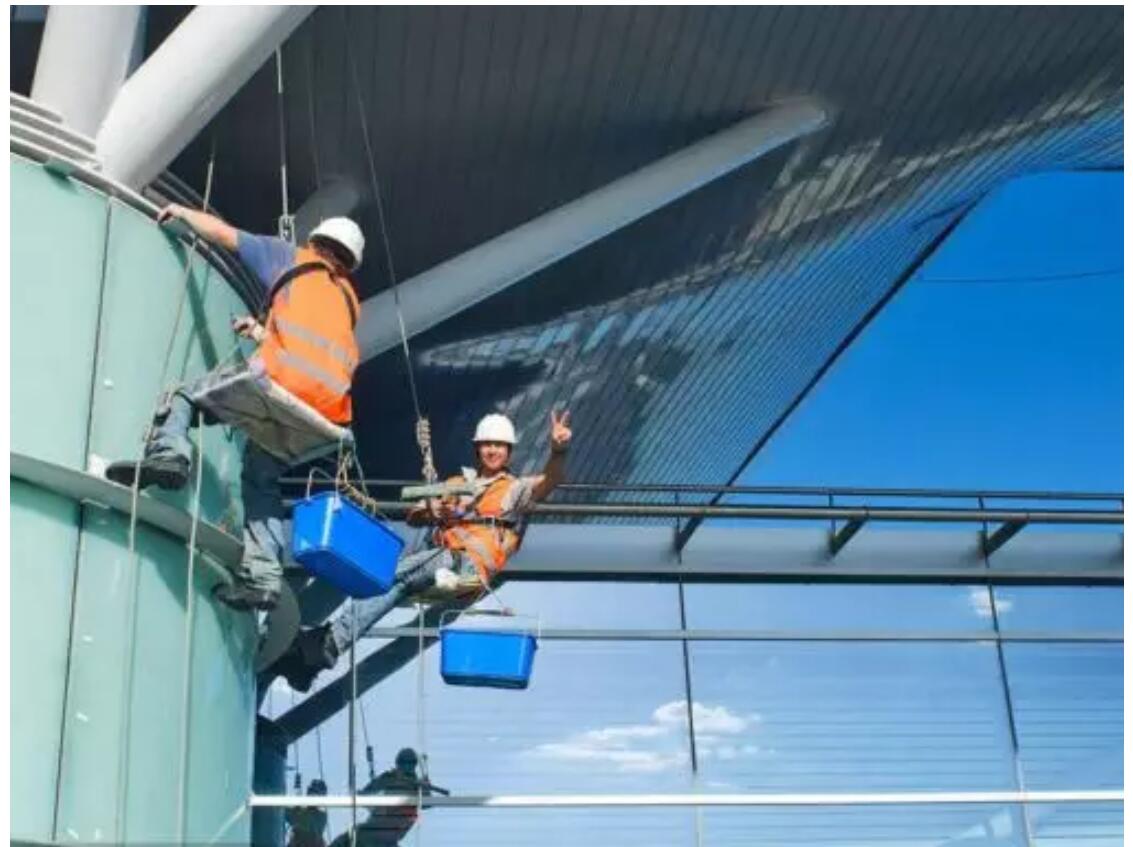

Application of hot aluminum zinc plating in the field of architecture

The application of hot aluminum zinc plating products in the field of architecture is basically the late processing into color coated plate widely used in the roof and wall of buildings.

In the aluminum zinc (55% AI, 43.5% Zn and 1.5% Si) substrate surface first do a layer of chemical conversion treatment, then spray extremely thin (5um) special primer, finally according to customer requirements coated with about 20um durability and processing of good color coating.

The product substrate has SGLCC, G345, G300, G550, coating thickness has AZ150, coating structure for light whole small zinc flower, coating varieties have PE, PVDF, SMP, HDP, coating structure has double-sided double coating and one side double coating and one side single coating, coating color according to customer demand.

Application considerations

1. Precautions for design and use

Aluminum – zinc plate should be used with caution under alkaline condition.

Avoid direct contact with other conductive materials for protection;

Wet wood and concrete also do not contact long aluminum zinc color plate;

Small roof slope suggested to use aluminum zinc plate;

The use of accessories (insulation, sealing and fasteners) should be considered simultaneously with the corrosion resistance of aluminum zinc coating.

2. Processing matters needing attention

The surface of the plate should not be damaged in rolling forming.

Embossed plate should pay attention to its depth and sharpness to ensure durability;

All cut edges shall be properly protected or not exposed;

No metal chips should be left on the plate when cutting and welding.

Long plate handling should avoid sagging board, should be stacked on the pad wood, and have a certain Angle to drain aluminum zinc coating.

3. Matters needing attention for maintenance

Complete cleaning (water) after construction;Under normal circumstances, the cleaning should be carried out once every 6 months, and the cleaning of the seaside and industrial polluted areas should be more frequent