1 Phenomenon Description

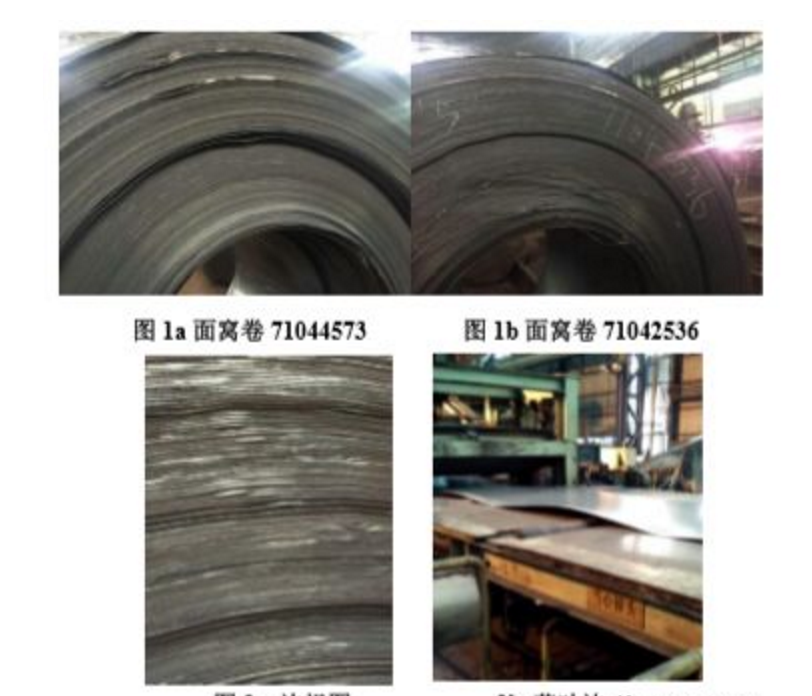

In a hot-rolled steel coil warehouse, nearly 400 tons of steel coils are rejected every month due to the abnormal coil shape, which seriously affects the secondary waste drop index of the factory. The abnormal coil shape is mainly the unilateral or bilateral steel coils with lotus leaf edge and edge roll (flanging), which looks like the surface nest, and is called the surface nest coil.Since the edge of the face socket has been rolled up and the plate shape is also arched, if the normal machine resurrection will damage the roll and the plate shape can not be corrected, it can only be revised or scrapped, causing huge quality loss.According to the investigation, this kind of steel coil finish rolling outlet plate shape is normal, laminar flow cooling is normal, so it is inferred that this defect is from the winding, a hot rolling technicians on this defect was analyzed and studied.Will face nest volume information were collected, and one by one at the scene confirmed the material object, from the point of physical roll, steel roll of the central stratification or big overflow edge, have obvious guide section steel roll edge scratch, it is after finishing line open-book falbala, from the point of coiler, 1 reel in the majority, from the thickness specification, mainly concentrated in between 2-4 mm.According to the above phenomenon, it can be determined that the roll of this kind of surface socket is caused by the guide plate of the take-up side. The following focuses on the in-depth analysis of the control link of the take-up side guide plate.

2 Cause Analysis

2.1 winding side guide board control strategy

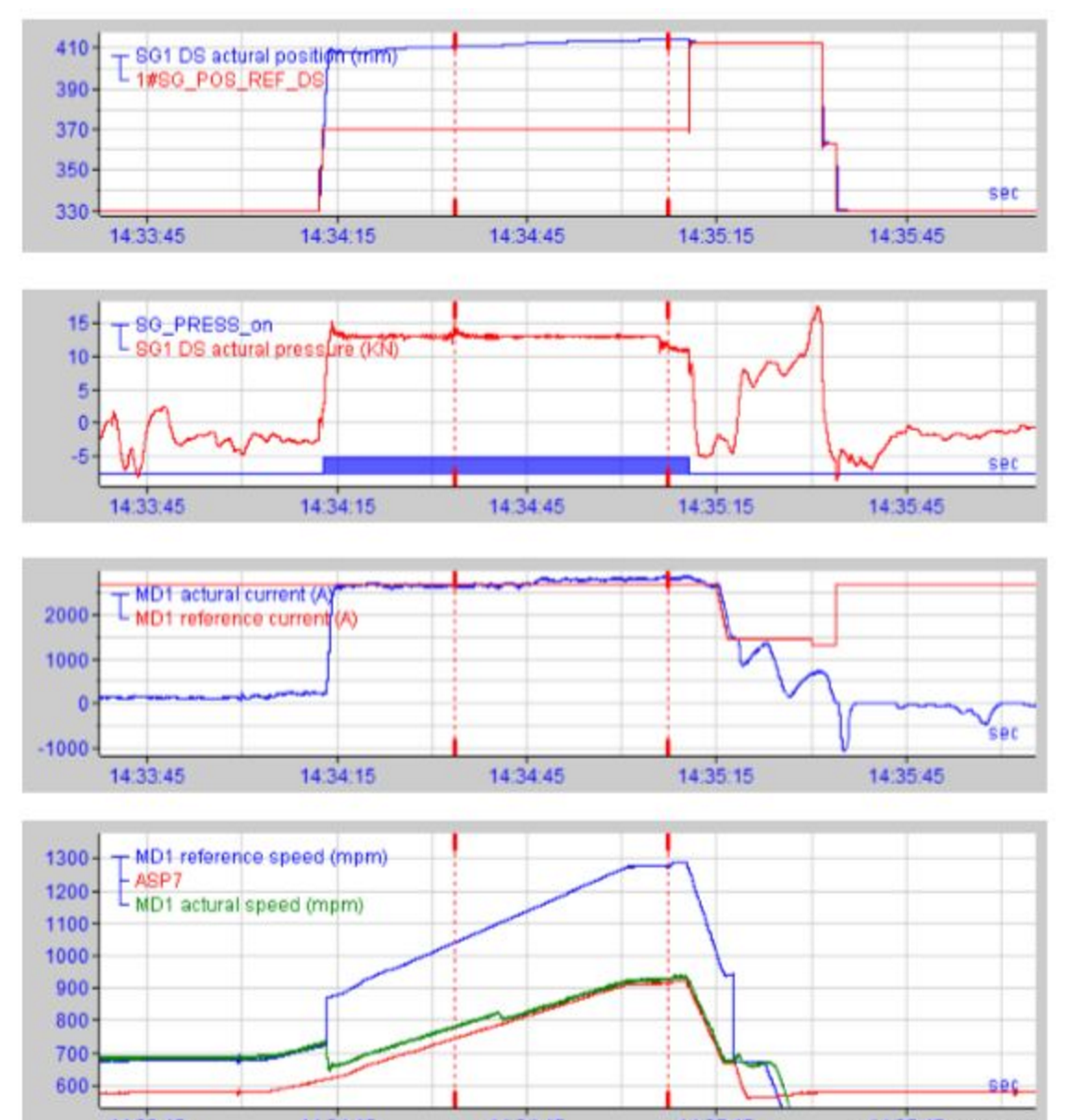

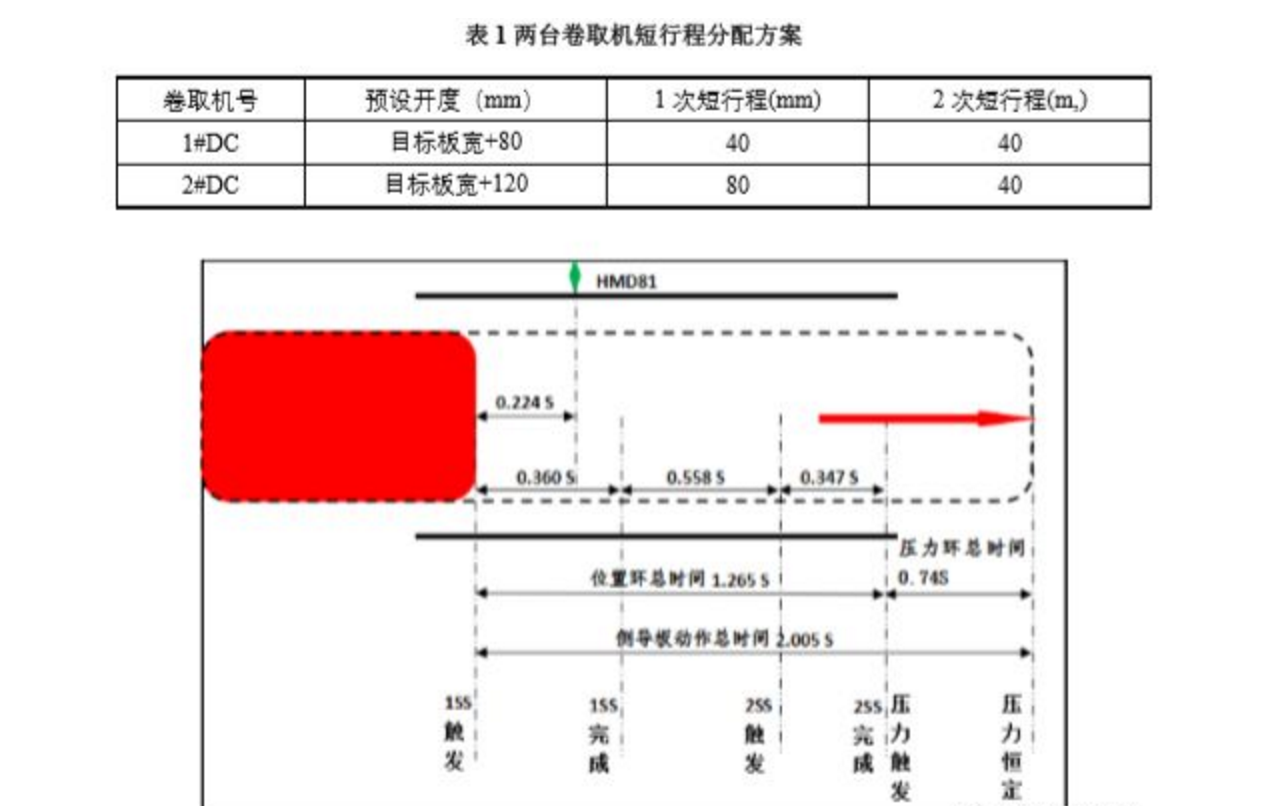

A hot rolling is a vertical transportation, on the roll quality requirement is very high, if there is a slight overflow, also can appear work side folding defects, so the side guide USES pressure control is good for roll shape, but to avoid head scrap steel, hot-rolled coil, a side guide to use two short stroke and full pressure loop control strategy, the side guide the preset opening and two short trip distribution as shown in table, short stroke on both sides of side guide action schedule same, SG no. 1, for example, a short trip to trigger timing for HMD71 after connecting strip head distance meet 9 meters, namely strip head has just landed on the side guide parallel segments,The trigger timing of the second short stroke is when the integral distance of the strip head reaches 14 meters after HMD71 is connected after the end of a short stroke, and the pressure link begins after the end of the second short stroke. In the pressure link, the drive side of the side guide plate is controlled by the target pressure closed-loop.

2.2 case study of typical face cavity volume

The material of the socket roll is SAE1017, the specification is 2.3*1020*C mm, 1#DC production.In the middle of the steel coil, there is obvious stratification. Within the stratification, there is a typical surface roll. The stratification is relieved by the outside roll, but the roll shape is uneven.

1) the guide USES is full pressure loop control strategy, the head pressure ring when entered into a state of constant, the transmission side guide trip to 78 mm, work side two short stroke to 40 mm, preset opening for B + 80 mm, transmission measurement guide side more than the work left 38 mm, including 20 m m to guide calibration of embedded, equivalent to guide on the strip head pressure ring 18 mm more stable when the trip, the 18 mm consists of two parts, one is the guide of the wear and tear, second, the deformation of the strip (general state of deformation for the transverse bending);

2) from the perspective of the speed of roll, the coil winding to the central roll speed is also slow down, this phenomenon should be a result of rising tension suddenly, and combining with the guide conditions, after the tension should be generated by the guide, the guide of unstable after the tension, leading to the volume fractal layered outside present uneven phenomenon, this is a kind of tension instability phenomenon;

3) at the end of the coil production, the manual operation of the guide plate is required to reduce the opening degree. The reason is that the pressure detection of the side guide plate suddenly becomes smaller, and the drum speed tends to increase and become untensioned. Therefore, the operator reduces the opening degree of the guide plate.

2.3 static friction force of the guide plate on the take-up side

(1) influence of static friction force of side guide plate

The setting of the target pressure of the side guide plate is related to the friction force suffered by the side guide plate. When the static friction force is large, the target pressure of the side guide plate must be large to push the side guide plate, otherwise the steel coil is badly wrong, but the excessive pressure of the guide plate causes great damage to the strip edge.Static friction force has the characteristics of reverse and change, and affected by width or strip shape change, strip of side guide reaction will be instantaneous jump, if you would have a side guide to squeeze to open at this moment, must overcome the pressure of side guide and change to the sum of the static friction force, or it will collapse to form surface litter volume, so need to accurately measure the side guide of friction.

(2) static friction force source of guide plate

The guide plate static friction force mainly comes from the gear rack and rack to meet the copper slider, a hot rolling and two hot rolling contrast, a hot rolling guide rail copper slider is three sliding friction, and the second hot rolling because of the guide wheel, sliding friction into rolling friction, greatly reduce the friction.