Color plate to cold rolled steel and galvanized steel as the substrate, after the surface pretreatment (degreasing, cleaning, chemical conversion treatment), in a continuous process of coating, after baking and cooling and made.

Colour coated board introduction

What is painted board

Painted plate, also known as color steel or PPGI steel.

It is made of cold rolled steel sheet and galvanized steel sheet, after surface pretreatment (degreasing, cleaning, chemical conversion treatment), continuous coating (roller coating method), after baking and cooling.

Color coated steel features

Color coated steel is light and beautiful, with good anti-corrosion performance, and can be directly processed. It provides a new raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry and electrical appliance industry, and plays a good effect of replacing wood with steel, efficient construction, energy saving and pollution prevention.

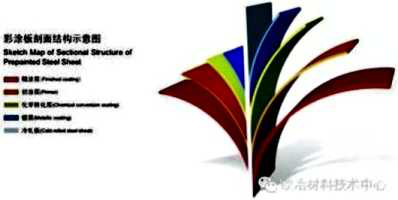

Color coated board structure

A color coating steel plate from the section is divided into five layers: steel substrate, metal coating (also some products directly use cold rolled substrate), chemical conversion layer, primary (primer), finish (finish)

Color coated board type

According to the substrate

According to the different substrates, there are cold rolled substrates, galvanized zinc substrates, hot galvanized substrates, aluminum zinc substrates.

Typical value of galvanizing layer is as follows (unit: g/m2) : electric galvanizing: 20/20, 36/36, etc.Hot dip galvanizing: 90/90/140/140, etc.;Hot aluminum zinc plating: 75/75, 90/90, etc.

According to the coating

Top coat: polyester (PE), silicon modified polyester (SMP), polyvinylidene fluoride (PVDF), high weather resistance polyester (HDP), functional coating (heat insulation, self-cleaning, anti-static, scratch resistance, etc.)

Primers: epoxy, polyester, polyurethane, etc