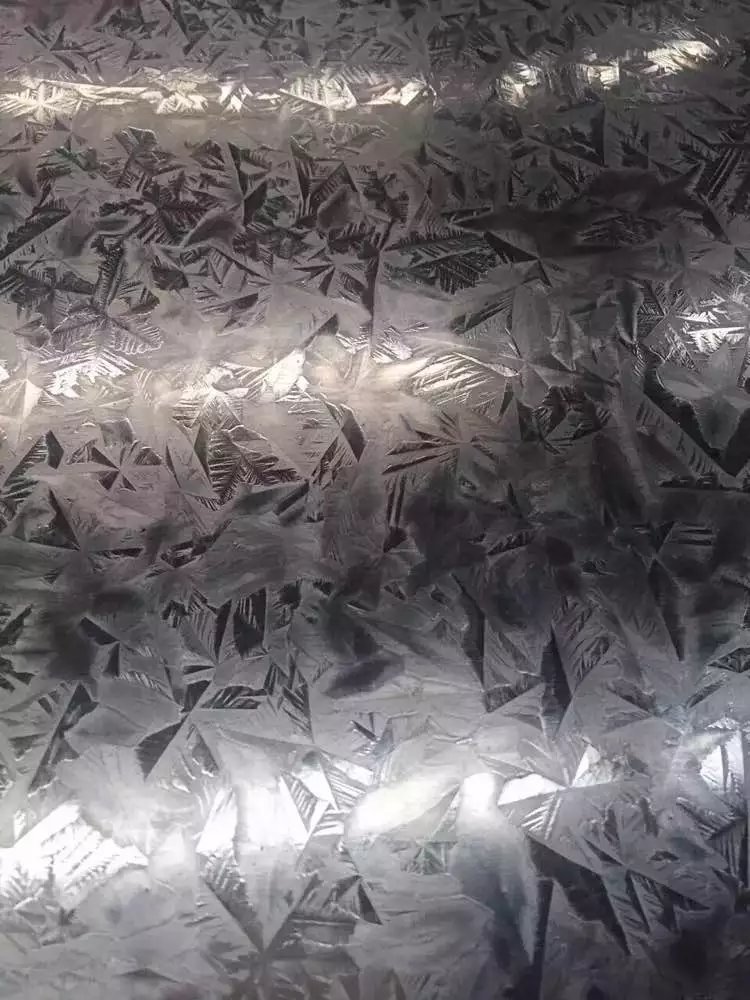

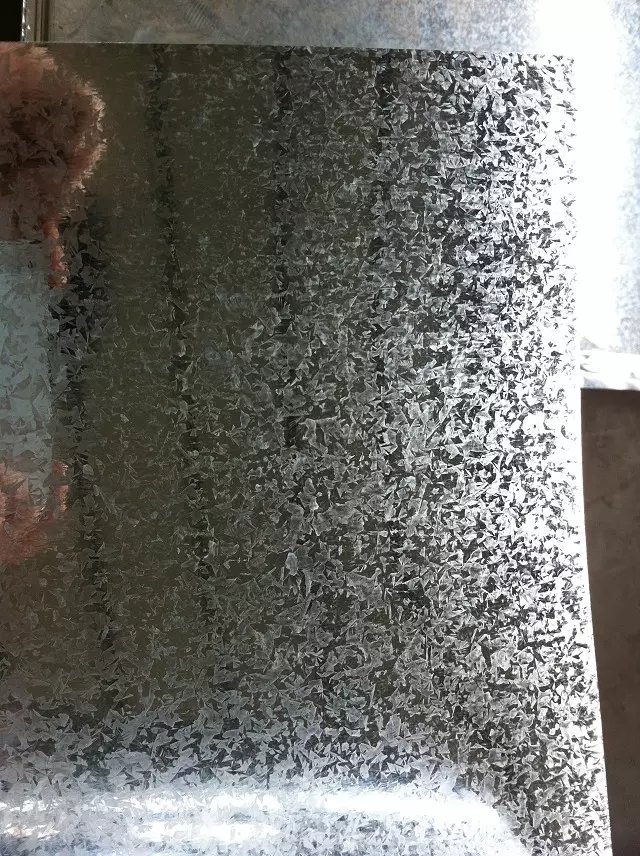

Galvanized Steel Appearance

(1) surface state: due to different treatment methods in the coating and plating process, the surface state of galvanized sheet is also different, such as ordinary zinc flower, fine zinc flower, flat zinc flower, zinc-free flower and phosphating treatment surface.German standard also provides for surface grade.

(2) galvanized plate shall have a good appearance, and shall not have harmful defects to the use of the product, such as no plating, holes, cracks and scum, over plating thickness, scratch, chromic acid dirt, white rust, etc.Foreign standards are not very clear about specific appearance defects.When ordering, some specific defects should be specified in the contract.

Galvanized Steel Performance

1) tensile test:

(1) performance indicators: generally speaking, only the structure, drawing and deep drawing galvanized sheet has tensile properties.Galvanized sheet for structure is required to have yield point, tensile strength and elongation.Only elongation is required for drawing.See the relevant product standards in “8” in this section for specific values;

(2) test method: the test method is the same as the general thin steel plate, see the relevant standard provided by “8” and the test method standard listed in “ordinary carbon steel sheet”.

(2) bending test:

Bending test is the main item to measure the technological performance of sheet metal, but the requirements of various national standards on galvanized sheet are not consistent.In Japan, bending test is required except for structural grade, building corrugated board and general corrugated board.

Requirements: general requirements galvanized sheet bending 180, the outer surface must not have zinc layer off, plate base must not have cracks and fracture.