7. Causes of white rust and black spots

The causes of white rust mainly include:

(1) poor passivation, insufficient or uneven passivation film thickness;

The surface is not oiled;

(3) residual water on steel surface;

(4) passivation is not completely dried;

(5) dampness or rain during transportation or storage;

(6) long storage time of finished products;

(7) galvanized sheet and other acid and alkali corrosive media contact.

White rust may develop into black spots, but the spots are not necessarily caused by white rust alone, such as friction spots.

8. The maximum allowable storage time

If oil is applied, packaging and storage are very convenient. Some products can be stored for more than one year, but it is better to use them for three months. If no oil is applied, the storage time is shorter, so as to avoid oxidation caused by long-term storage.

9. Tolerance

The length tolerance is not allowed to be negative, and the maximum is not allowed to be +6mm

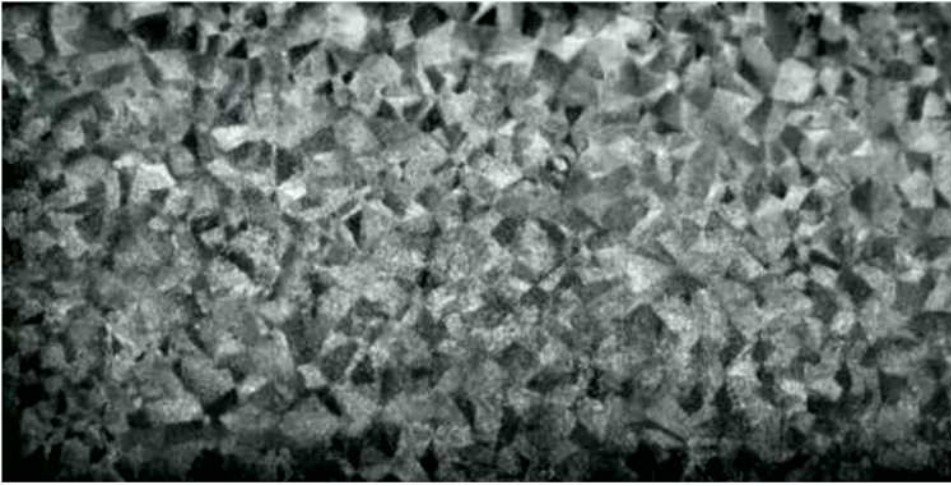

10. Classification of spangles

Zinc flower is divided into large spangles, small spangles, no spangles.

11. Protection principle of zinc layer

In the corrosive environment, zinc will be preferred to steel corrosion, so as to protect the steel base, and the zinc layer in corrosion resistance will be due to the line into a certain protective film to prevent too fast oxidation, delay the corrosion speed, and can be in the maintenance of brush zinc paint and other ways to prevent steel corrosion, ensure the mechanical properties of the material and other safety properties.

12. Passivation principle

The passivation film can be formed by chromate passivation treatment of galvanized sheet, the trivalent insoluble in water in solution passivation group plays the role of skeleton, while the hexavalent aluminum in solution is soluble in water, which can play the role of passivation again when the passivation film scratches, and has the healing effect of passivation film.Therefore, within certain limits, passivation film can prevent steam or moist air direct erosion of galvanized sheet, play a protective role.

13. Method of corrosion resistance

There are three methods to test the corrosion resistance of hot galvanized sheet:

(1) salt spray test;(2) moisture test;(3) erosion test.