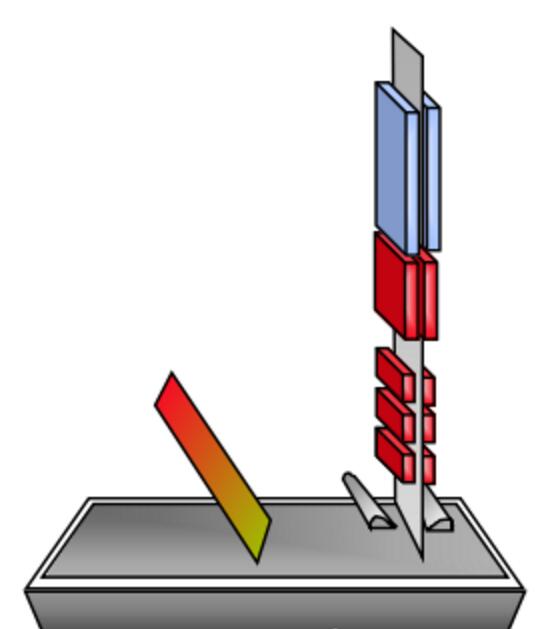

Principle of zinc coating protecting steel plate

In the atmosphere, zinc is much more resistant to corrosion than steel, usually several times more resistant than steel.

1) physical effects:

The zinc coating on the surface of the steel plate blocks the contact between the steel plate and the corrosion medium, so that the steel plate can avoid the corrosion effect of the corrosion medium.

2) electrochemical action:

When the substrate of galvanized steel and the zinc layer are exposed to the corrosive medium at the same time (such as the scratch and incision of the zinc layer), because the electrode potential of zinc is lower than the electrode potential of iron, zinc gives priority to corrosion and protects the substrate.

The main process of galvanizing

Hot plating and electroplating are the two main processes of galvanized, now we mainly say hot dip galvanized

Hot dip galvanizing: the melting point of steel and zinc is quite different. The melting point of pure iron is 1534°C, while the melting point of zinc is only 1534°C

At 419°C, the process of galvanizing treated steel by dipping it directly into molten zinc is called hot plating

Product classification and features

Classification: according to the coating types, it is divided into GI (pure zinc coating), GA (zinc ferroalloy coating), 55% ai-zn (aluminum zinc coating, GALVALUM E), 5% ai-zn (GALFAN), Aluminizing (aluminum plating), zn-5ai-3mg (zinc aluminum alloy coating).

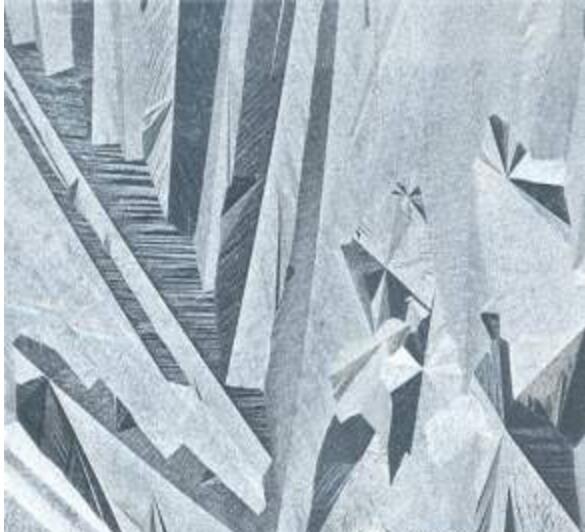

Hot-dip galvanized products (GI)

Features: beautiful surface, good corrosion resistance, good processing.

Hot-dip galvanized alloy products (GA)

Features: zinc-iron alloy coated steel plate has good adhesion, good corrosion resistance and good weldability after painting.

Hot aluminized zinc products (GALVALUME)

Features: good corrosion resistance, 2-6 times of hot dip galvanized, this is the sample exposure in different environments for more than 15 years, and galvanized steel plate comparison;Good temperature resistance, no discoloration at 300°C, up to 700°C if discoloration is allowed.Excellent thermal reflective surface.