Detection of weight of organic or inorganic coating after treatment

Weight method: reference standard has GB/T 9792-2003.Peel off the coating with different solutions, then weigh the weight difference before and after peeling off the coating, and calculate the coating weight.

X-ray fluorescence spectrometry: since most of the post-treatment agents are organic solutions, the weight of the coating can be converted into the coating weight by measuring the weight of the characteristic elements in the coating.

| Coating types | Eigenelement |

| Phosphating film | Phosphorus(P) |

| Passivation coating | Chromium(Cr) |

| Chrome-free passivation film | Silicon(Si)or Titanium(Ti)or(Zr) |

| Chrome-free fingerprint film | Silicon(Si)or Titanium(Ti)or(Zr) |

Due to different suppliers provide different post-treatment agent formula, such as Japan paka, Germany henkel and so on.Therefore, it is best to establish standard curves with standard samples from the same supplier as the sample.

Determination of iron content in hot-dip galvanized ferroalloy coating

According to the literature, there is a direct relationship between the iron content and the pulverization of the product.

ISO 17925-2004 determination of chemical constituents in zinc or aluminium layers by gravimetric, ICP and atomic absorption spectrometry.

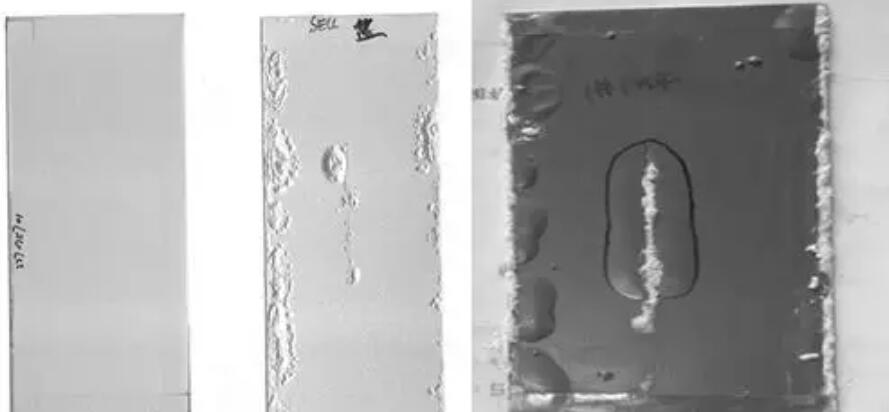

Neutral salt spray test to evaluate corrosion resistance of galvanized sheet

Professional equipment

Atmosphere of water mist with certain concentration of sodium chloride (50g/L)

A certain temperature and humidity (35±2°C)

A certain pH (6.5 ~ 7.2)

The test time can be according to the user’s requirements, such as 48h, 72h, etc

To evaluate the foaming, rusting, adhesion reduction, corrosion spread from scratch, etc

The uniformity and porosity of coating thickness and corrosion spreading degree under salt spray were evaluated.Most conventional, most useful, most extensive accelerated corrosion

Executive standard:

ASTM B117

Gb: GBT1771 GBT10125