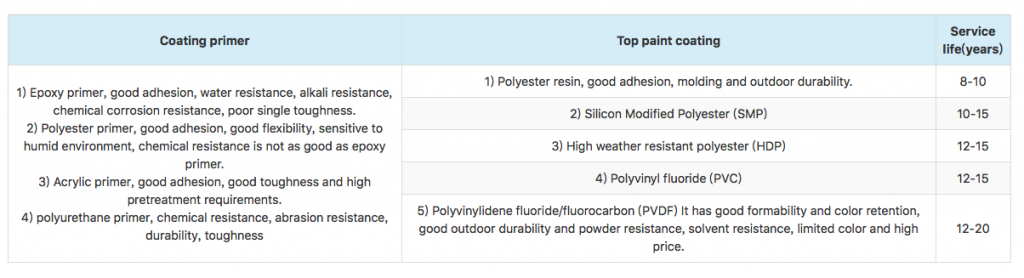

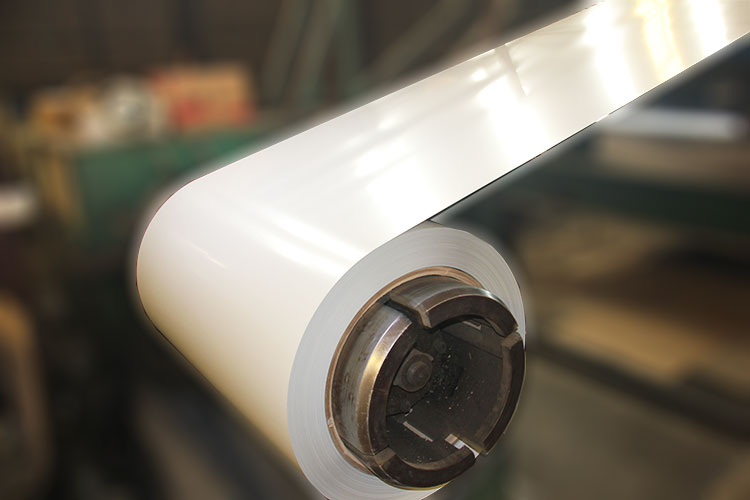

The prepainted steel sheet in coil is a product obtained by subjecting a hot-dipped galvanized steel sheet, an galvalume steel sheet, or an aluminum sheet to a surface chemical treatment (coating) , followed by baking and curing.

- The total thickness of the pre-panted galvanized steel coil is composed of the base steel – coating -primer – top paint – protective layer thickness. The top paint thickness is 10-25μm, and the back paint thickness is 5-20μm. The thinner the base steel thickness, the higher the price of the ppgi steel coil, because the processing cost becomes higher.

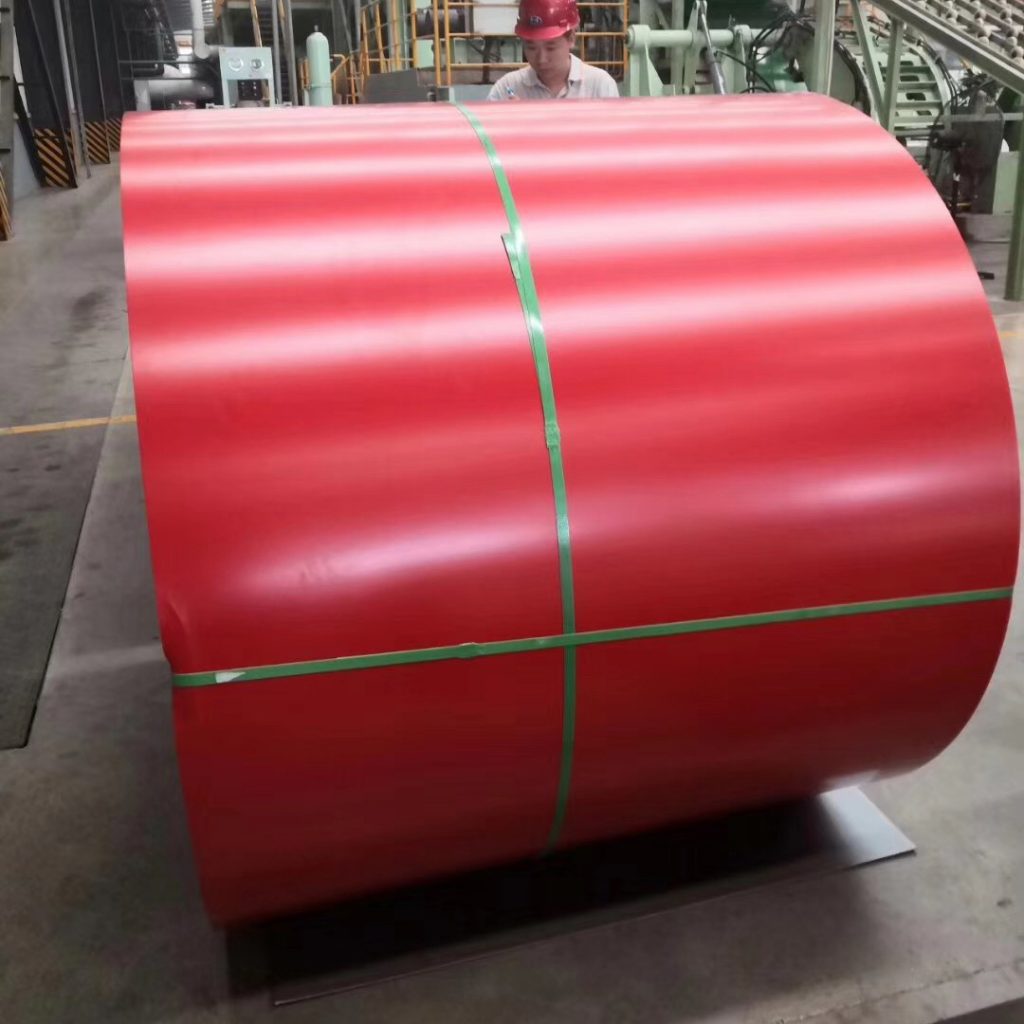

- Usually the paint coating material is polyester (PE) and the color of the back paint is white grey. The color can be customized according to the RAL color card or customer samples. Special patterns can be made, such as wood grain, flower print, camouflage, brick.

1) PPGI also known as prepainted galvanized steel coil and color coated steel coil, with a hot dip zinc coated steel sheet substrate.

2) PPGL also known as prepainted galvalume steel coil, with a galvalume steel sheet as a substrate.

PPGI Steel Coil Specification

| Product name | Prepainted Galvanized Steel Coil |

| Material | CGCC, DX51D,Q195,Q235 |

| Zinc | 20-120g |

| Thickness | 0.13-0.8 mm |

| Width | 600-1250 mm |

| Color | all RAL color , as client’s request |

| Paint | top paint : 10-30mic back paint: 5-25 mic |

| Paints | PE, SMP, HDP, PVDF |

| T bend | |

| Pencil hardness | >2H |

| Coil ID | 508/610mm |

| Coil weight | 3-8tons |

| Surface | glossy and matt |

| Glossy | 30%-90% |

| Package | standard export package (Detailed picture is as follows) |

| Hardness | soft (normal), hard, full hard(G300-G550) |

| HS code | 721070 |

| Country of origin | China |

| Business type | Supplier and manufacturer |

| Brand name | GRSSTEEL |

PPGI&PPGL Coil Price Reference

The prepaint galvanized steel coil and PPGL prices keep changing, which is calculated based on raw material(Hot rolled sheet), width, thickness, paint, and zinc. Here is only reference price, Please email us to get the precise price.

Based on 1000 mm width – FOB qingdao – 2019.02.11

| Paint Top 10/Back 5(micron) | Paint Top 15/Back 7(micron) | Paint Top 20/Back 10(micron) | Thickness (mm) |

| $809.00 | $847.00 | $898.00 | 0.15 |

| $765.00 | $795.00 | $836.00 | 0.19 |

| $739.00 | $764.00 | $797.00 | 0.23 |

| $725.00 | $746.00 | $773.00 | 0.28 |

| $698.00 | $714.00 | $736.00 | 0.35 |

| $693.00 | $708.00 | $728.00 | 0.38 |

| $688.00 | $701.00 | $718.00 | 0.45 |

| $690.00 | $699.00 | $712.00 | 0.58 |

| $707.00 | $716.00 | $729.00 | 0.62 |

| $704.00 | $713.00 | $724.00 | 0.65 |

PPGI&PPGL Sheet

The decoiler machine unwinding, leveling, fixed length, cut the prepainted galvanized steel coil into a flat PPGI sheet of the required length and width and is processed into a PPGI&PPGL roofing sheet of various styles by a roll forming machine, such as corrugated steel sheet, wave tile, roman longtile profile.

Pre-painted Steel Products

Matt PPGI

The matt PPGI has big wrinkle PPGI and small wrinkle PPGI. The paint coating thickness is 20μm-45μm, which is used for roofing sheet which is not easy to discolor and has a longer service life.

Polyester color coated sheet in coil

It is coated on a metal sheet with a polyester coating and baked at a high temperature.

Features:

Good adhesion, formability, outdoor durability, chemical resistance

Application:

Roofing sheet of Industrial workhouse, warehouse.

PVDF prepainted steel sheet in coil

It is coated on a metal plate with PVDF paint and baked at high temperature.

Features:

High durability, high flexibility, impact resistance, still maintain good color and luster for 15 years outdoors

Application:

For buildings with high corrosion resistance

Brick pre-painted steel sheet in coil

The brick pattern is printed on a galvanized or galvalume steel sheet.

Application:

Outdoor decoration, interior wall

Marble color coated coil

The marble pattern is printed on a galvanized or galvalume steel sheet.

Application:

Indoor, outdoor wall

Matt Colour coated coil

Attached to a galvanized or galvalume steel sheet with a high performance polyester coating containing abrasive particles.

Features:

The surface of the coating is ultra-low gloss, close to the natural matte feel

Application:

High-rise buildings, villas, roofing tiles

Camouflage color steel coil

Print camouflage patterns on galvanized or aluzinc steel sheets.

Application:

Indoor, outdoor wall

Wooden design prepainted steel coil

Print wood grain patterns on galvanized or aluzinc steel sheets.

Application:

House door, garage door

HDP Colour coated steel coil

Attached to galvanized or galvalume steel sheet with high performance polyester coatings.

Features:

UV resistant, better durability, between polyester and PVDF

Application:

For buildings with high corrosion resistance

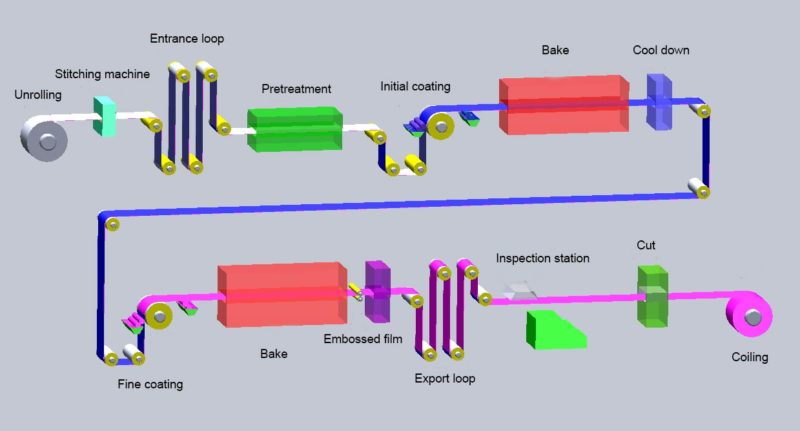

Pre-painted Steel Sheet in Coil Production Line

The manufacturing of double-coated, double-baked pre-coated steel sheets with good weather resistance, primarily used in construction.

PPGI Coil Production Process Flow Chart

Unrolling → Stitching machine → Entrance loop → Pretreatment → Initial coating → Bake → Cool down → Fine coating → Bake → Embossed film → Export loop → Inspection station → Cut → CoilingIn the above process, if the cleaning degreasing process is not handled well, the adhesion of the primer of the color coated plate to the galvanized sheet is not good, and it is easy to cause the top coat of the color coated steel coil to fall off during the press forming process.

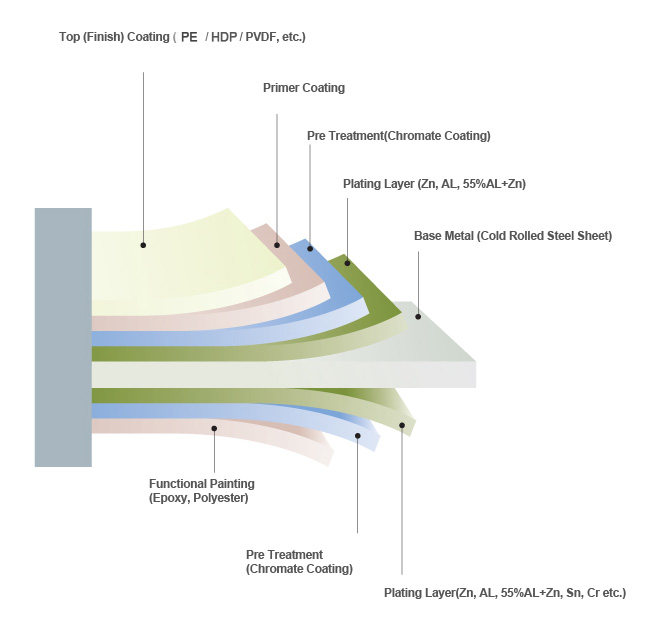

PPGI & PPGL Sheet Coating Layer

- Top (Finish) Coating (PE/HDP/PVDF, etc.)

- Primer Coating

- Pre Treatment (Chromate Coating)

- Plating Layer (Zn, AL, 55%AL+Zn)

- Base Metal (Cold Rolled Steel Sheet)

- Plating Layer (Zn, AL, 55%AL+Zn, Sn, Cr etc.)

- Pre Treatment (Chromate Coating)

- Functional Painting (Epoxy, Polyester )

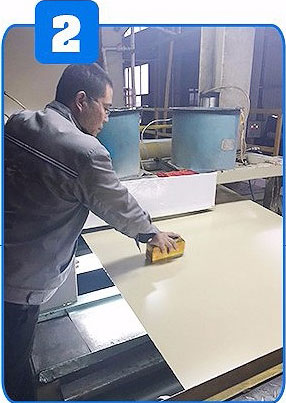

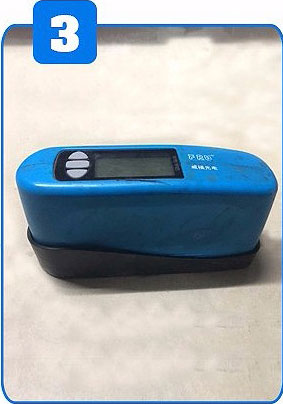

PPGI Quality Control

PPGI & PPGL steel quality control according to the following:

- coating thickness test

- color difference test

- gloss test

- T bend

- tensile test

- impact test

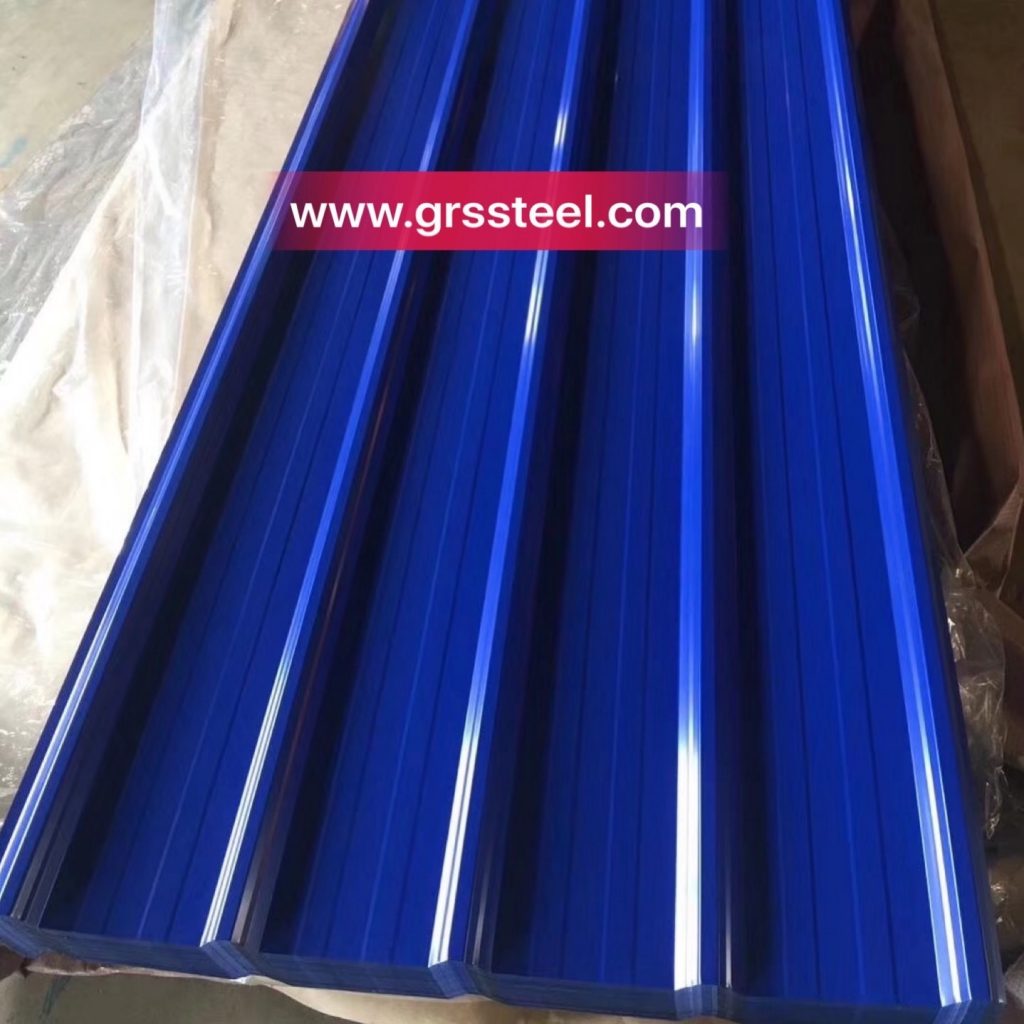

PPGI paint coating